(+1) 866-314-2240

(+1) 407-666-6623

1780 Business Center Lane, Kissimme Fl, 34758, United States.

info@tensik.com

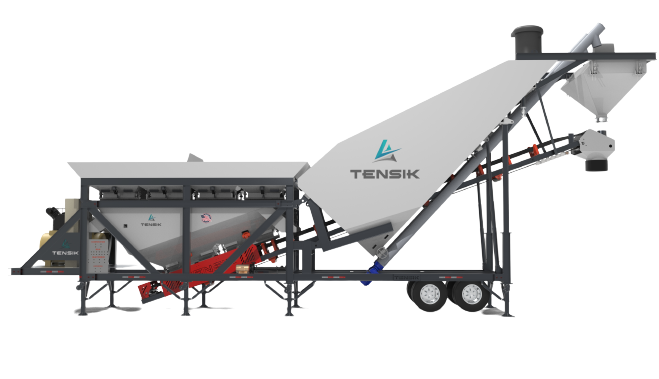

The DECUM 1 is a portable concrete batching plant capable of mixing aggregates, cement, water, and additives to produce high-quality concrete.

It is designed for quick set up and is movable with one truck . The system includes a 10 hp water pump, a 12yd³ aggregate batcher and a 60-ton cement silo. It also features a 3″ turbine type water meter, a water strainer, and a butterfly discharge valve with pneumatic actuator and solenoid valve . The system is equipped with a central lubrication panel and a self-erected hydraulic system.

– 12yd Aggregate Batcher Split in 2

– 30” x 39 ft / 15 H.P. Transfer truck Conveyor

– 60TON -400 BBL Ton Cement Silo

– 12 Cubic Yard Cement Batcher

– 10 H.P. / 240 Gallon Air Compressor

– 3” Metered Water Badger Meter With 10H.P. Pump

– Tandem Axle Transportation System

– Central Lubrication

– Self Erecting Hydraulic System

Aggregate – 12 Cubic Yard Aggregate Batcher:

– 2 Scale hoppers Bin weight capacity for 12yd of concrete.

– 3/16” plate on the vertical sides and 1/4” plate on the sloped sides

– (2) clamshell gate

– (2) 4” x 8” air cylinders and an inching valve for greater control of material flow.

– Proximity switch confirms the gate is closed.

– (2) MVE Electric type vibrators Oli Brand

– 4 x 20K, NTEP certified, load cell system with a rated scale capacity

– Test weight hangers installed

Aggregate Transfer Conveyor:

Belt width 30 in – Belt drive 15 H.P. TEFC – 350 / F.P.M. – 650 T.P.H. drive motor with reducer and backstop

4 inch Idler roller and Return roller Cema B PPI Brand or Superior – Self Cleaning Blade ,

12 inch drum pulley and wing pulley PPI Brand or Superior

Skirt Boards Installed

Discharge head includes a water inlet, (5) admix ports

Cement Storage:

– 58 tons Cement Silo 400 BBL

– Fluidizing Kit 8 aeration pads in silo cone

– 10″ Butterfly Valve or Slide gate depend on configuration

– Single Flange, Cast Iron Disc Pneumatic Drive Actuator 1/2″

– 4 Way Double Solenoid Closed Port

– Silo Level Sensor Indicator (High and Low)

– Pressure valve

– Dust collector

– WAM Silotop Zero264 sq ft filter surface Pulse

– Jet air cleaning system 7 polypleat filter elements

99.99% filtration efficient

– Bottom mounting flange

– Capacities are based on a cement weight of 74.0lb per cubic foot

– 2 Cement Transfer Screws.

– 10 inch diameter screw conveyors, each powered by a 25 hp Motor Drive WAM

– SELF-ERECTED HYDRAULIC SYSTEM

Batcher Capacity:

– Cement 5 Tons – Enough for a 12yd batch Truck

– 10” butterfly discharge valve including pneumatic actuator and solenoid for material flow control.

– Proximity switch confirms the gate is in closed position.

– Complete aeration system with full size pads,.

– MVE vibrator is mounted

– includes (4) S-beam style load cells and summing box 5K TYPE

– Test weight hangers include

– HOPPERJET WAM

Air Specification:

– 10 H.P. / 240-gallon air compressor with ¾” outlet INGERSOLLRAND

– A weather tight NEMA enclosure for Main plant solenoids.

– Each valve is equipped with a “Quick” cut off to allow

the customer isolation of the individual valves for easy maintenance.

– Air system complete from air compressor to all pneumatic equipment on the plant

– 5 H.P. Blower for Aeration Regenerative Blower, 173 CFM, 230/460V

Water System:

– Water meter (turbine type) 3 in Badger Meter with electronic scalable transmitter and pulse head

– 3” turbine type water meter.

– 3” water strainer.

– 3” butterfly discharge valve with pneumatic actuator and solenoid valve

– Complete piping to discharge head

– 10 H.P. Water PUMP

Electrical System:

– 300 amp Panel 480 volt

– Enclosed box Motor Starter For all Motors

– The main disconnect and motor starters are wired to each motor.

– All equipment is wired and tested prior to shipment.

– Automatic Batch Controller