The Enigma: Wet Batch Pant or Dry Batch Plant

In the world of concrete production, two distinct methodologies stand tall – Wet Batch and Dry Batch of Concrete Batching Plants. Each approach offers unique benefits and brings its own set of advantages to the construction table. Join us as we delve into the intriguing world of these, exploring their differences and uncovering the unparalleled benefits they offer.

DIFFERECES

THE WET BATCH WONDER

Wet Batch Concrete Batching Plants are a symphony of precision and finesse. In this method, all ingredients, including aggregates, cement, water, and additives, are meticulously combined in a central mixer. This thorough blending creates a consistent, homogenous mixture, ensuring the highest quality of concrete production. The key benefit lies in the advanced control over the water-to-cement ratio, resulting in impeccable workability and enhanced concrete strength.

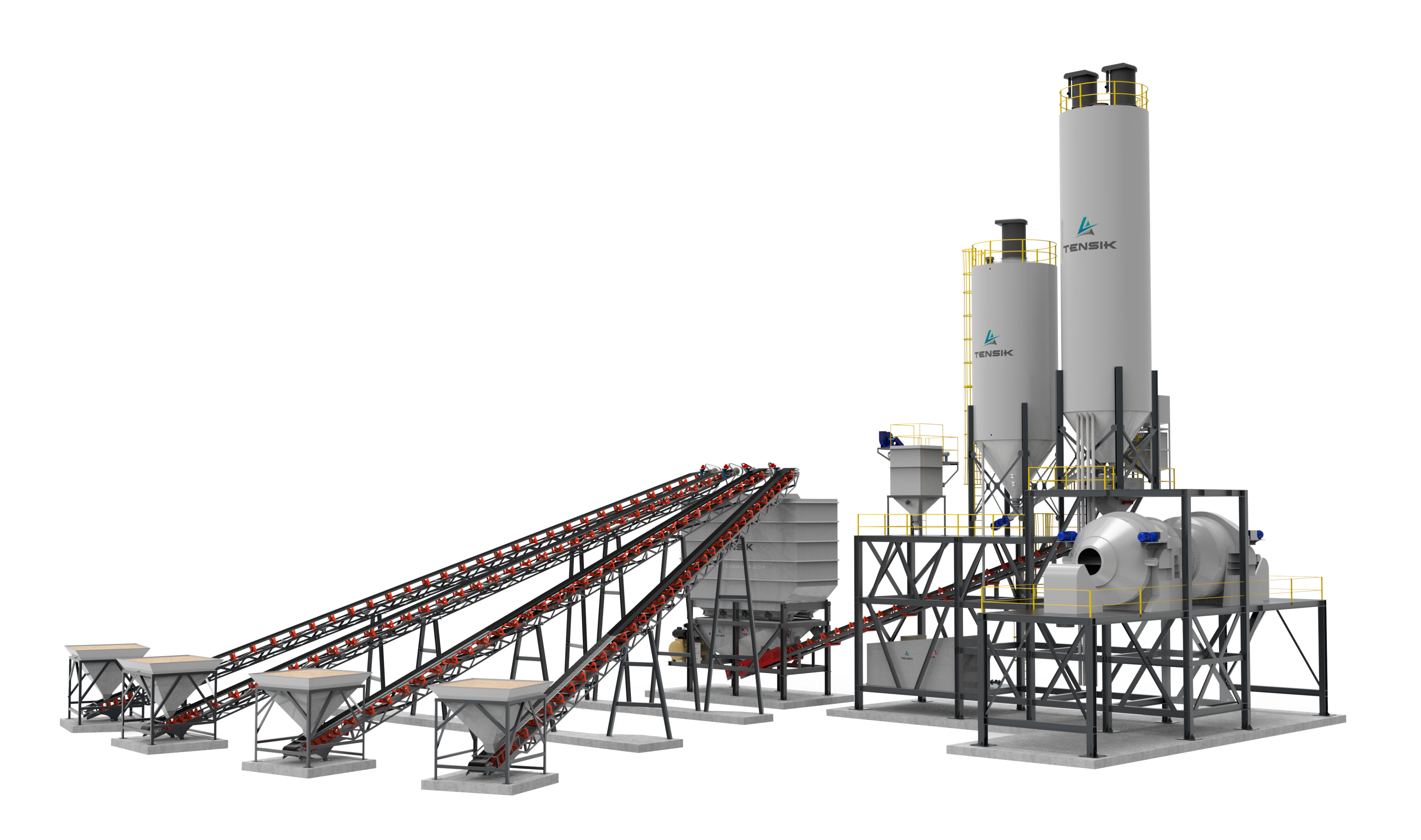

DRY BATCH BRILLIANCE

In contrast, Dry Batch Concrete Batching Plants introduce water only at the construction site, making them a versatile and resource-efficient solution. Dry ingredients, such as aggregates, cement, and additives, are accurately weighed and loaded into the mixer truck. The mix is then blended during transit, offering flexibility for on-the-go construction projects. The primary advantage of this method is rapid deployment and ease of transportation, saving time and resources.

WHAT DO THESE OPTIONS OFFER TO YOU?

Enhanced

Quality Assurance:

Both Wet Batch and Dry Batch Concrete Batching Plants share a common goal – superior concrete quality. Wet Batch plants provide meticulous control over the mixing process, ensuring consistent results, and reducing the likelihood of material segregation. On the other hand, Dry Batch plants offer precise measurement of ingredients, minimizing material waste and guaranteeing reliable and repeatable concrete production.

Eco-friendly Innovations:

Both Wet Batch and Dry Batch methods share a commitment to sustainable construction practices. By accurately measuring ingredients and reducing wastage, these batching plants contribute to eco-friendly project execution. Additionally, the latest advancements in concrete batching technology ensure efficient energy usage and reduced emissions, leaving a greener footprint on the environment.

Project Versatility:

The choice between these largely depends on the nature of your construction project. Wet Batch plants shine in large-scale ventures, where concrete quality and consistency are paramount. Their ability to optimize the water-cement ratio makes them a go-to option for projects demanding exceptional performance. Dry Batch plants, on the other hand, excel in on-the-go applications, offering more than quick setup, making them an ideal choice for smaller-scale projects or those requiring frequent site changes.

In the world of concrete batching, the Wet Batch and Dry Batch methods each present a compelling case for construction excellence. Wet Batch plants stand tall with their precision-controlled mixing, ensuring impeccable concrete quality, while Dry Batch plants offer unparalleled deployment. Choose the method that best aligns with your project’s requirements and embrace the power of innovation, efficiency, and environmental responsibility in the realm of concrete production.

Contact

Address:

Phone:

Email:

Leave a Reply

You must be logged in to post a comment.